Designers love the term sustainability as it is their go-to when they can’t think of another way to sell their designs!! (I’m sure every designer would relate)

On a more serious note, they strive to construct a future along those lines because everyone is now aware of its importance and it is no longer a buzzword. Companies are now taking steps to ensure that their operations are sustainable, and governments are introducing regulations to encourage more sustainable practices.

Designers are becoming more aware of the value of a more in-depth, process-oriented approach. One such Korean designer observed the staple use of tableware in people’s lives and created a 100% natural material as an alternative to glass, ceramics, and other traditional raw materials used to manufacture tableware.

Designer: SooA Choi

Ceramics are the most used materials for the production of tableware. These materials are great but involve a lot of unsustainable properties concerning production. The material is complex to machine and can lose structural integrity if cut incorrectly or with the wrong tools. It requires high levels of expertise and leads to the wastage of raw materials. Machining ceramics and CMCs can be capital-intensive.

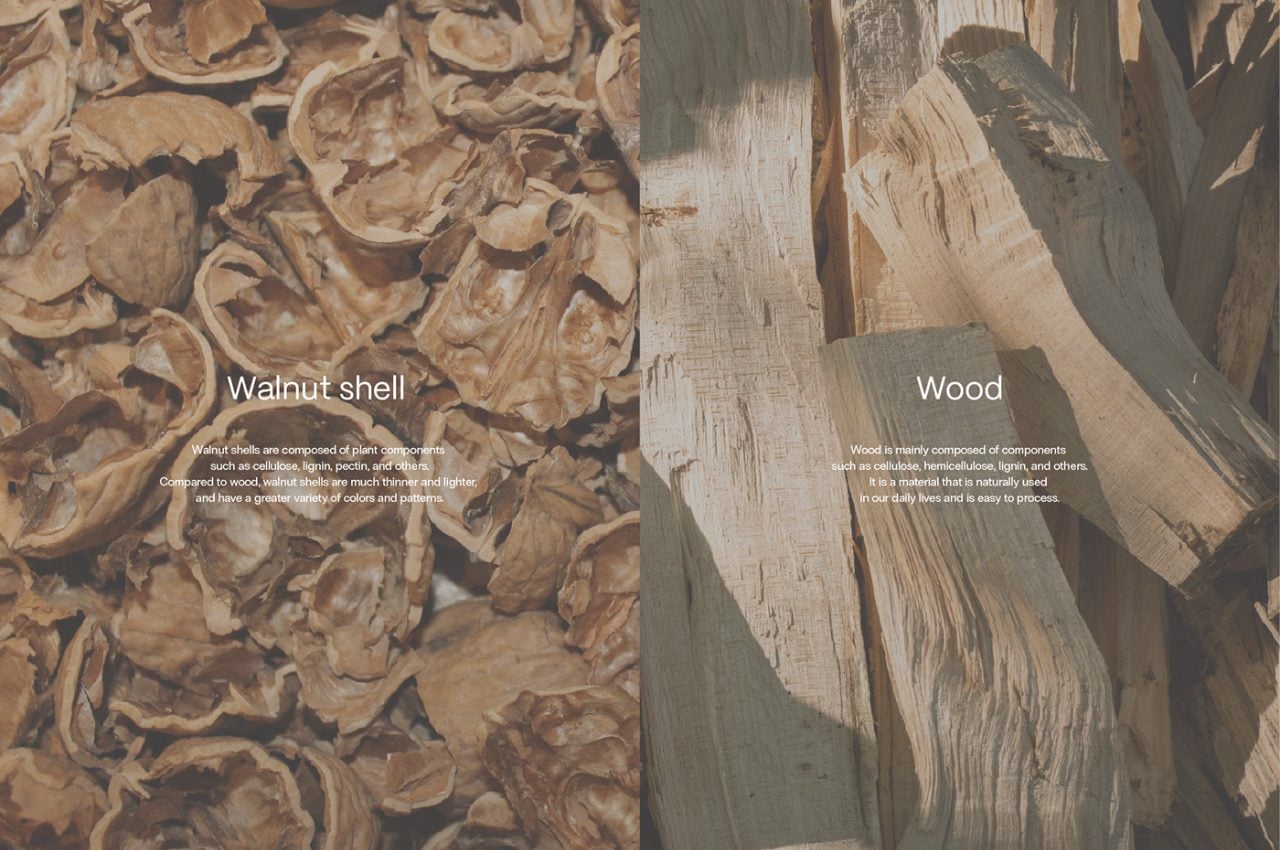

NOS is a mixture of walnut shells, pine resin, and Canauva Powder. It presents new CMFs with diverse colors, patterns, and light transmission as a result of grinding enormous volumes of walnut shells into various sizes. The primary binding agent is pine resin.

After being separated from the kernel, the shell of a walnut is considered waste and is discarded. The waste can be transformed into an entire plate from which to eat. Converting waste into a resource is an important aspect of sustainability.

The qualities of a walnut shell and wood overlap and can be used in everyday situations. Walnut shells are dry and hard, which works to their benefit since it stops insects from entering via holes and crevices, and it also makes them almost odorless. Pine resin is tree sap that is naturally antimicrobial and safe to consume in tiny doses. However, the soldering of pine resin is hazardous to one’s health and should be avoided during the manufacturing of NOS. Walnut shells are more durable than other natural materials, which wear away with frequent use.

The manufacturing technique for this material is quite simple and highly sustainable; no artificial additives are used. It only needs the appropriate ratio of binders, a mold, and ground walnut shells. To produce the required shape, the substance is poured into the mold. In the event of undesirable results during the NOS production process, the previous procedures can be repeated and no product is wasted. The completed form removed from the mold is fired at a high temperature of over 400 degrees to apply the glaze. Carnauba wax is poured onto it to increase durability and prevent scratches.

NOS is a versatile material used in various forms and sizes. As suggested it is used for tableware like small and large plates, glasses, vases, etc. It can also be used for other decors around the house since the aesthetic value of the finished piece complements a zen interior design.

The post Tableware gets a new innovation with walnut shell materials becoming the new normal first appeared on Yanko Design.

from Yanko Design

0 Comments