Nature has been solving the problem of lightweight, load-bearing structure for hundreds of millions of years. Chen Xu, designing for RestBase, decided to take notes. The Camp Napper is a portable camping pillow whose form is derived from two specific biological sources: the surface texture of fungal spores, which informed the pillow’s contact face, and the hollow vascular structure of plant stems, which shaped its core. The outcome is a product that performs as well as it looks.

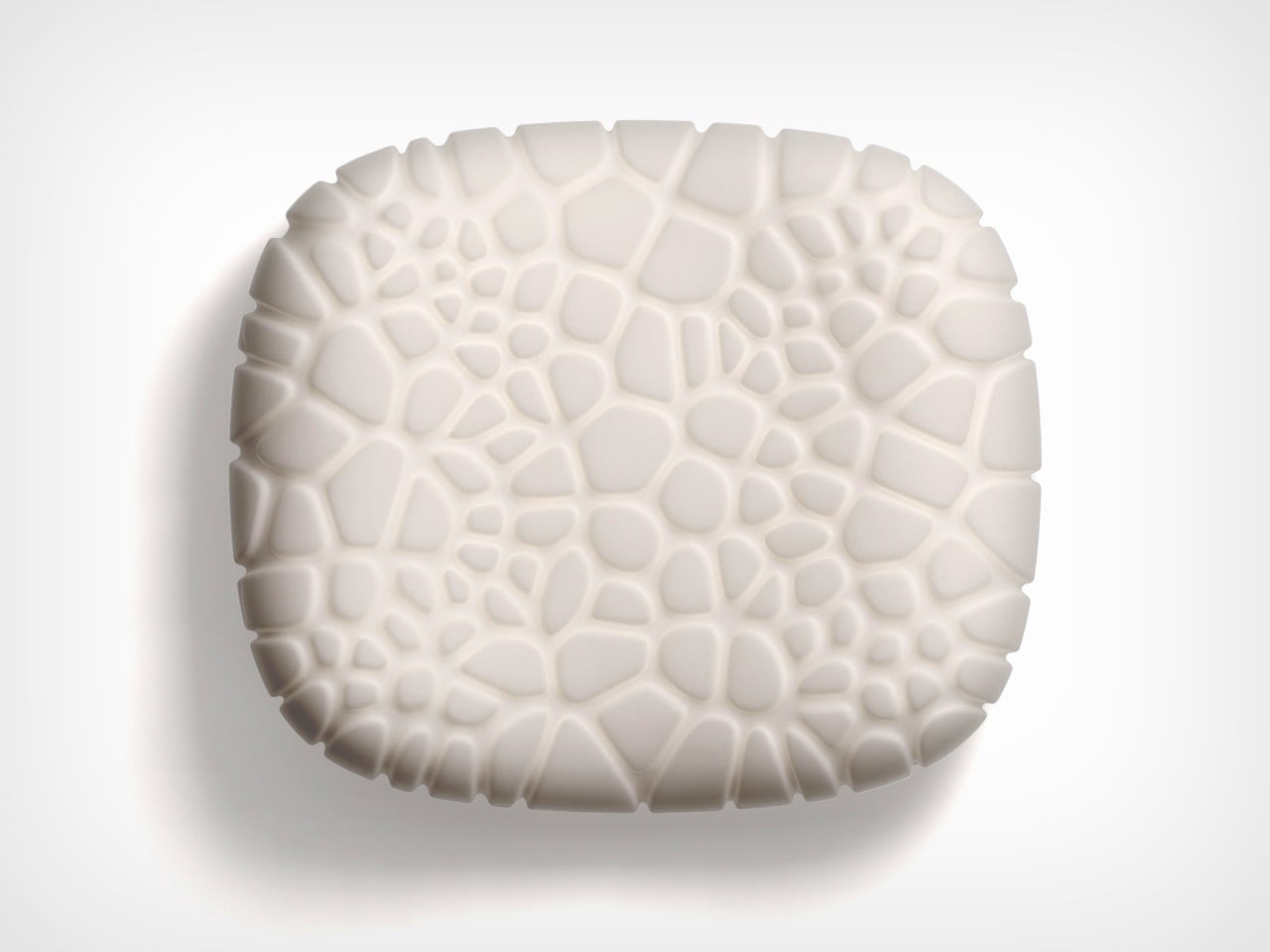

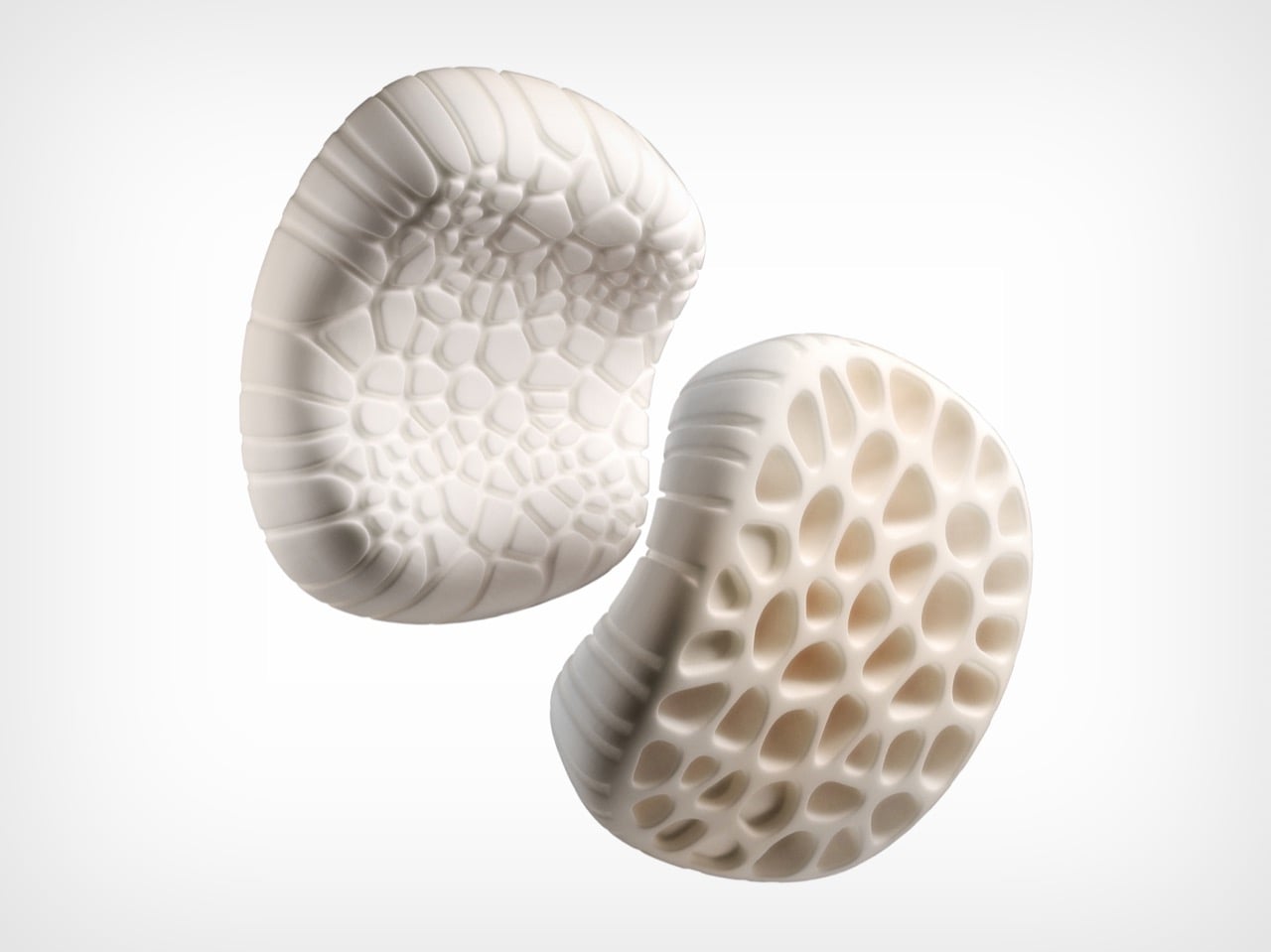

Using Voronoi polygon modelling, the design team mapped how pressure from a sleeping head distributes across the pillow’s surface, then engineered protrusions and recesses to respond to that data. The front face features raised cellular structures that increase the contact area between pillow and skin, improving comfort while simultaneously channelling airflow to keep things cool. The back face offers four distinct tactile zones depending on orientation, giving users a degree of customisation that is rare in camping gear. Also, a little warning but: trypophobia alert.

Designer: Chen Xu

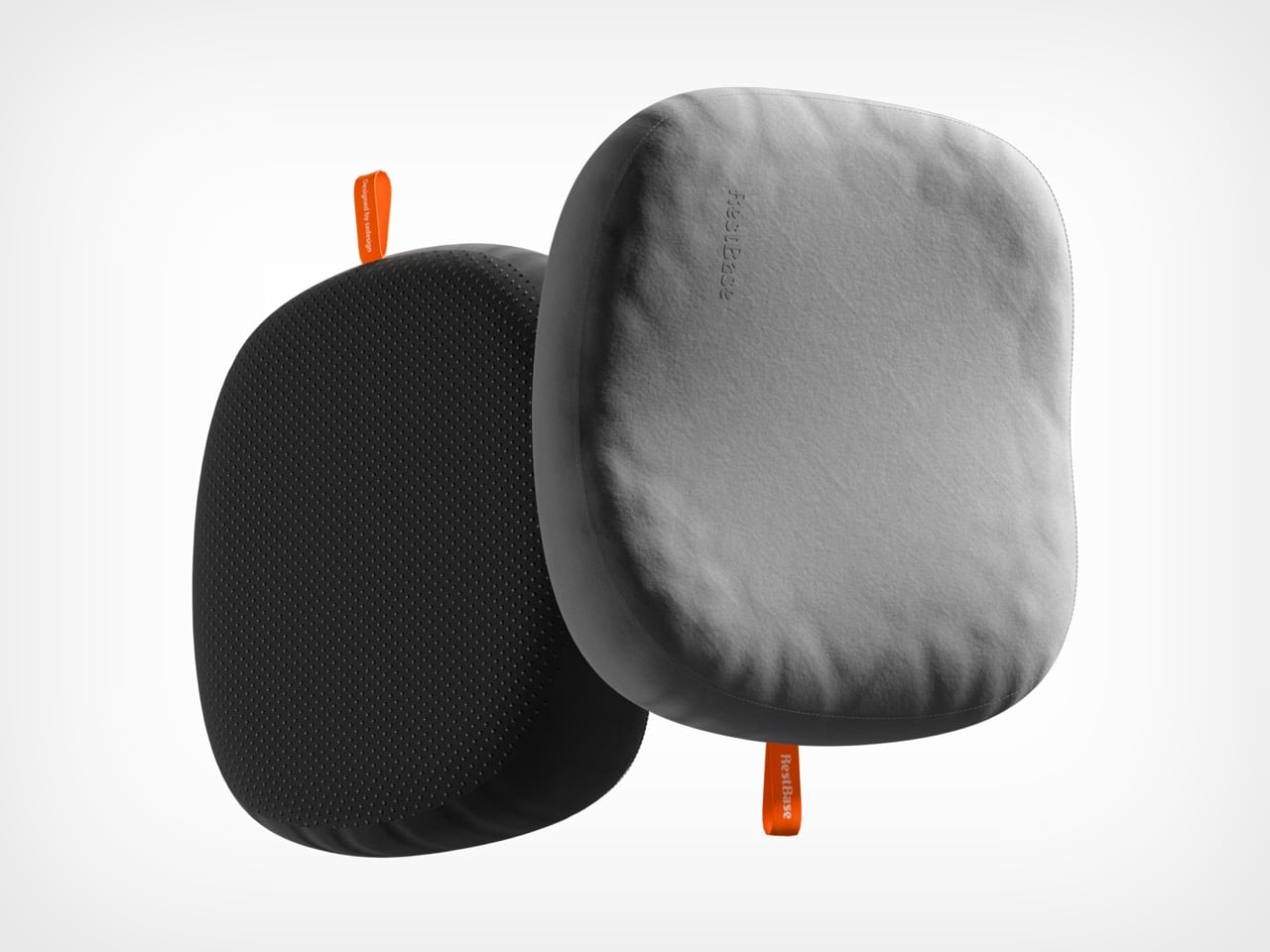

The core replicates the hollow geometry found in plant stems, achieving a structure that sheds mass without compromising its ability to hold form under repeated compression. Total weight lands at around 400 grams, and the whole pillow compresses into its storage bag at roughly the dimensions of a water cup, making it genuinely packable rather than merely marketed as such.

Memory foam was selected for its ability to conform to different sleepers while maintaining the structural geometry of the bionic surface. Anti-slip rubber particles on the base keep the pillow in place across the varied surfaces camping tends to involve, from sleeping pads to camp chairs to hotel floors. RestBase positions the Camp Napper across indoor and outdoor contexts, and the material specification backs that up without demanding a different product for each one.

The project ran from March to December 2024 in Beijing, with the team conducting pressure simulations using volunteer data before building the mathematical model that generated the bionic surface structure. Mold development required continuous adjustment of material ratios and foaming parameters to meet yield and appearance standards. The finished product carries all of that process lightly, presenting as something organic and considered rather than laboured. For a category where most innovation stops at inflation valves and stuff sacks, that is a meaningful place to arrive.

The post The Most Advanced Camping Pillow of 2026 Looks Like It Grew in a Forest first appeared on Yanko Design.

from Yanko Design

0 Comments